The R&D of Kamps follows 3 directions

1) Increasing aeration performance

Performance of our AIRMAX aerators are measured and developped according the last version of the following standard:

BS EN 12555-15: Waste water treatment plants- Measurement of the oxygen transfer in clean water in aeration tanks of actived sludge plants.

NF EN 12555-15 ou NBN EN 12-255-15 : Station d'épuration: Mesure de performance des aérateurs.

DIN 12255-15: Kläranlagen -Teil 15: Messung der Sauerstoffzufuhr in Reinwasser in Belüftungbecken von Belebungsanlagen:

Acceptable other standard are the STORA Zuurstoftoevoervermogen in beluchtingssystemen, ASCI:Measurment of Oxygen Transfer in clean water, ATV-M209 E: ,

The test should be performed by international laboratories like for example: Cebedeau, ULG, FUL, Cemagref, Lovap, Witteveen + Bos, Laboratoria VanVooren, Becewa...

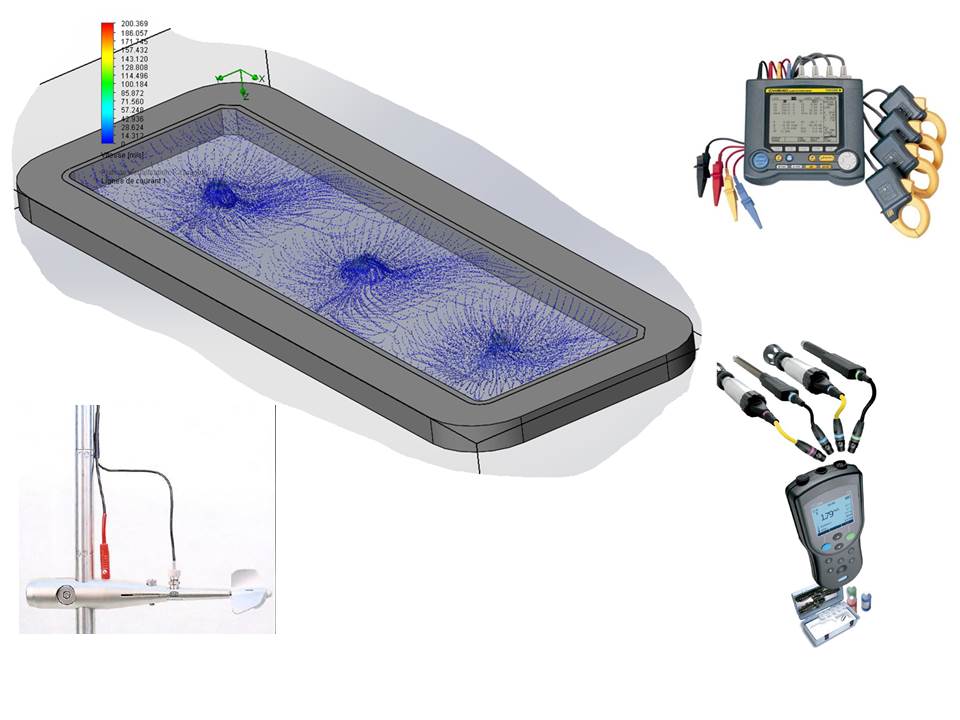

KAMPS has 2 aeration tanks with a maximum capacity of 2000m³ each for full scale test and comparaison test and 1 test tank with a capacity of 50m³ for the first design testing.

Kamps has its own full solar panel installation for piloting the SOLAIRMAX on long terms.

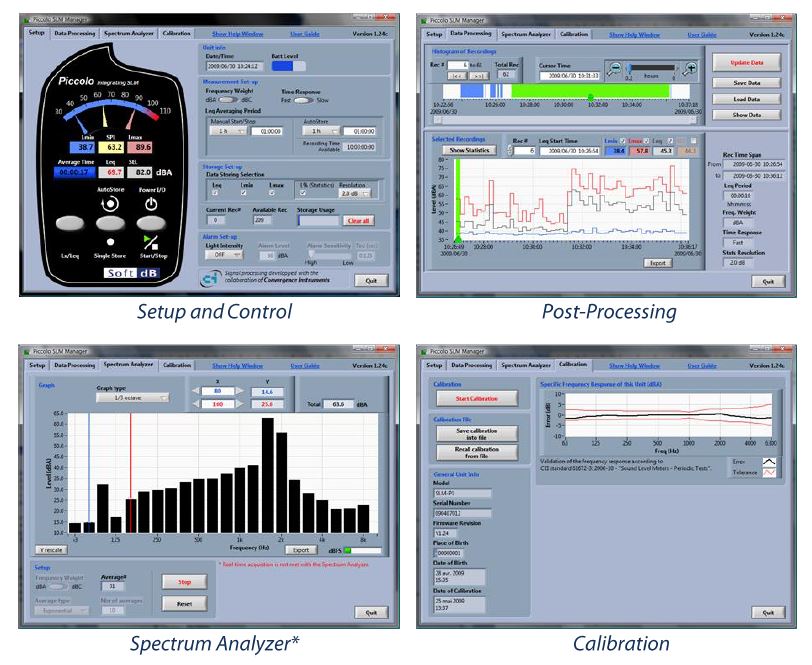

KAMPS has its own material to measure all surface aerators performances: O2 probes, double wattmeter with harmonic an energy integration, streamvelocity impeller, aplha factor tank test, sulfite dosing system, vibration control, sound meter with sepctrum,...

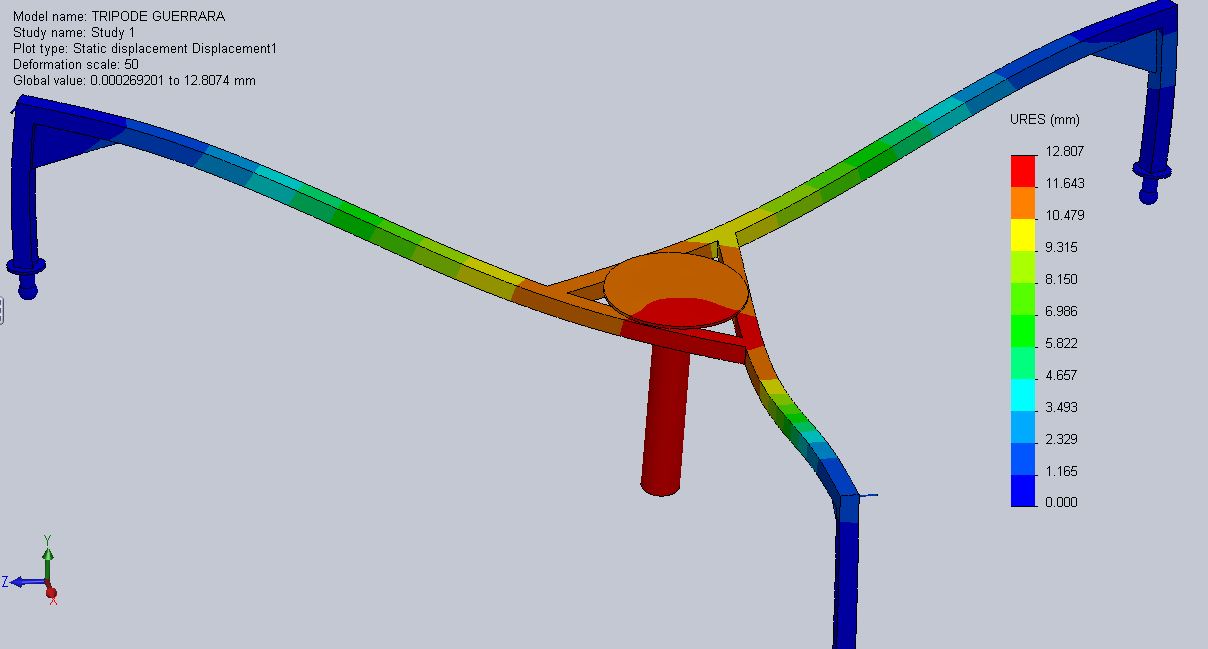

2) 3D design

Kamps designs each project with the last computer technology and the use therefore the FEA (finite elements Analysis).

3) Kamps' partners

Kamps collaborates with international companies (General Electric, Schneider Electric,..) and universities as long term partnership.