Sludge thickening - Gravity Belt Thickeners

OMEGA SD range

Designed for continuous mechanical thickening of municipal or industrial sludge

- Continuous thickening

- Belt width : from 0,50 to 2,50 m

- Filtration length : 2 m

- Sludge flowrate: up to 40 m3/h

- Very clean operation

- Easy maintenance and supervision

- Low energy consumption and operating costs

- Material : stainless steel 304L, 316L industrial sludge

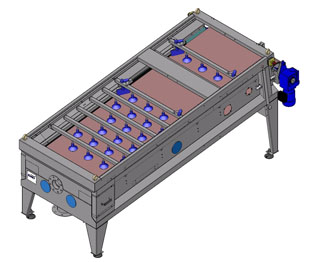

OMEGA MD range

Designed for continuous mechanical thickening of municipal or industrial sludge

- Continuous thickening

- Belt width : from 1 to 3 m

- Filtration length : 3 m

- Sludge flowrate : up to 80 m3/h

- Very clean operation

- Easy maintenance and supervision

- Low energy consumption and operating costs

- Material : stainless steel 304L, 316L or othe

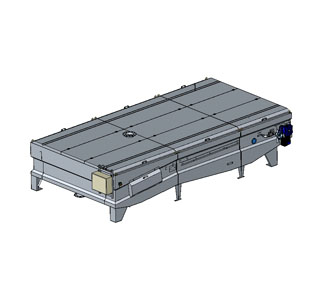

OMEGA LD range

Designed for continuous mechanical thickening of  municipal or industrial sludge

municipal or industrial sludge

- Continuous thickening

- Belt width : from 1 to 3 m

- Filtration length : 4m

- Sludge flowrate: up to 100 m3/h

- Very clean operation

- Easy maintenance and supervision

- Low energy consumption and operating costs

- Material : stainless steel 304L, 316L or other

OMEGA THC range

Designed for continuous mechanical thickening of municipal or industrial sludge. Especially aimed to very high capacity installations.

- Continuous thickening

- Belt width : from 1 to 3 m

- Filtration length : 5m

- Sludge flowrate : up to 200 m3/h

- Very clean operation

- Quick and easy supervision

- Low energy consumption and operating cost

- Material : stainless steel 304L, 316L or other

Sludge dewatering – Belt Filter Presses

OMEGA SC range

Designed for the continuous mechanical dewatering of municipal and industrial sludge in small capacities.

- Belt width : 0,60 and 1 m

- Sludge flowrate : up to 6 m3/h

- Easy maintenance and supervision

- Low energy consumption and operating costs

- Very clean operation

- Full enclosure for safety and odor extraction

- Material : stainless steel 304L, 316L or other

OMEGA 100 000 range

Designed for the continuous mechanical dewatering of municipal and industrial sludge in small and medium  capacities.

capacities.

- Belt width : 1 to 2 m

- Sludge flowrate: up to 12 m3/h

- Low energy consumption and operating costs

- Clean operating system

- Very clean operation

- Easy access for supervision and maintenance

- Visual control of the sludge during dewatering

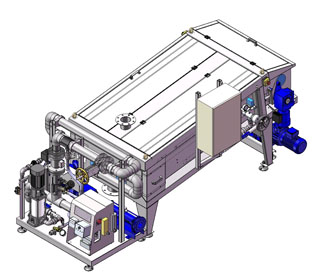

OMEGA 1000 range

Designed for continuous mechanical dewatering of municipal and industrial sludge in medium and big capacities.

- Belt width : 1 to 3 m

- Sludge flowrate : up to 30 m3/h

- Low energy consumption and operating costs

- Clean operating system

- Very clean operation

- Easy access for supervision and maintenance

- Visual control of the sludge during dewatering

- Material : stainless steel 304L, 316L or other

Sludge thickening and dewatering –Compact Combined System

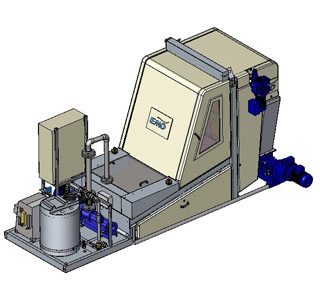

COMBINED SYSTEM range OMEGA CC

Designed for continuous thickening and dewatering of municipal and industrial sludge in small capacities.

- Belt width : 0,60 and 1,20 m

- Sludge flowrate : up to 15 m3/h

- compact design for real space saving

- Easy maintenance and supervision

- Low energy consumption and operating costs

- Full enclosure for safety and odor extraction

Sludge thickening and dewatering – Combined System

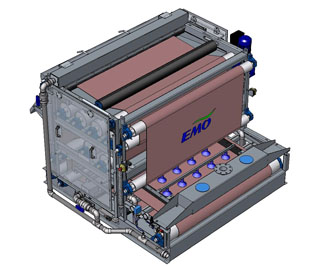

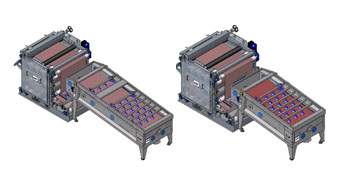

COMBINED SYSTEM range 100 000 / range SD or MD

Designed for continuous thickening and dewatering of municipal and industrial sludge in small and medium capacities.

- Belt width : 1 to 2,50 m

- Sludge flowrate: up to 40 m3/h

- Easy maintenance and supervision

- Reduced operating costs

- Full enclosure for safety and odor extraction

- Various configurations : “long” or “high” version

- Material : stainless steel 304L, 316L or other

Sludge thickening and dewatering – Combined System

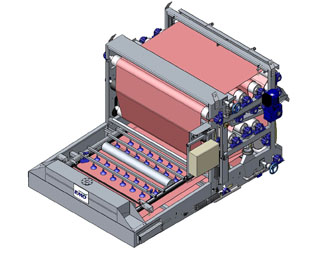

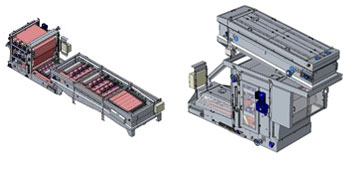

COMBINED SYSTEM range 1000 / range MD, LD or THC

Designed for continuous thickening and dewatering of municipal and industrial sludge in medium and big capacities.

- Belt width : 1 to 2,50 m

- Sludge flowrate: up to 150 m3/h

- Easy maintenance and supervision

- Reduced operating costs

- Full enclosure for safety and odor extraction

- Various configurations : “long” or “high” version

- Material : stainless steel 304L, 316L or other

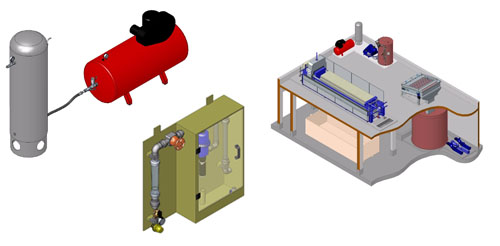

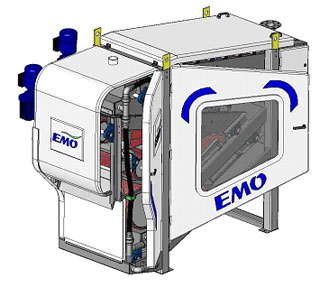

Sludge dewatering – Plate Filter Press

Designed for dewatering of municipal and industrial sludge in small or big capacities.

- Manual or automatic plate Shifting System

- Full automatic system with "inteligent" scraper

- Various accessories : electrical control panel, Drip tray, process engineering,high pressure washing system, pneumatic system, acid washing system control panel for the whole process